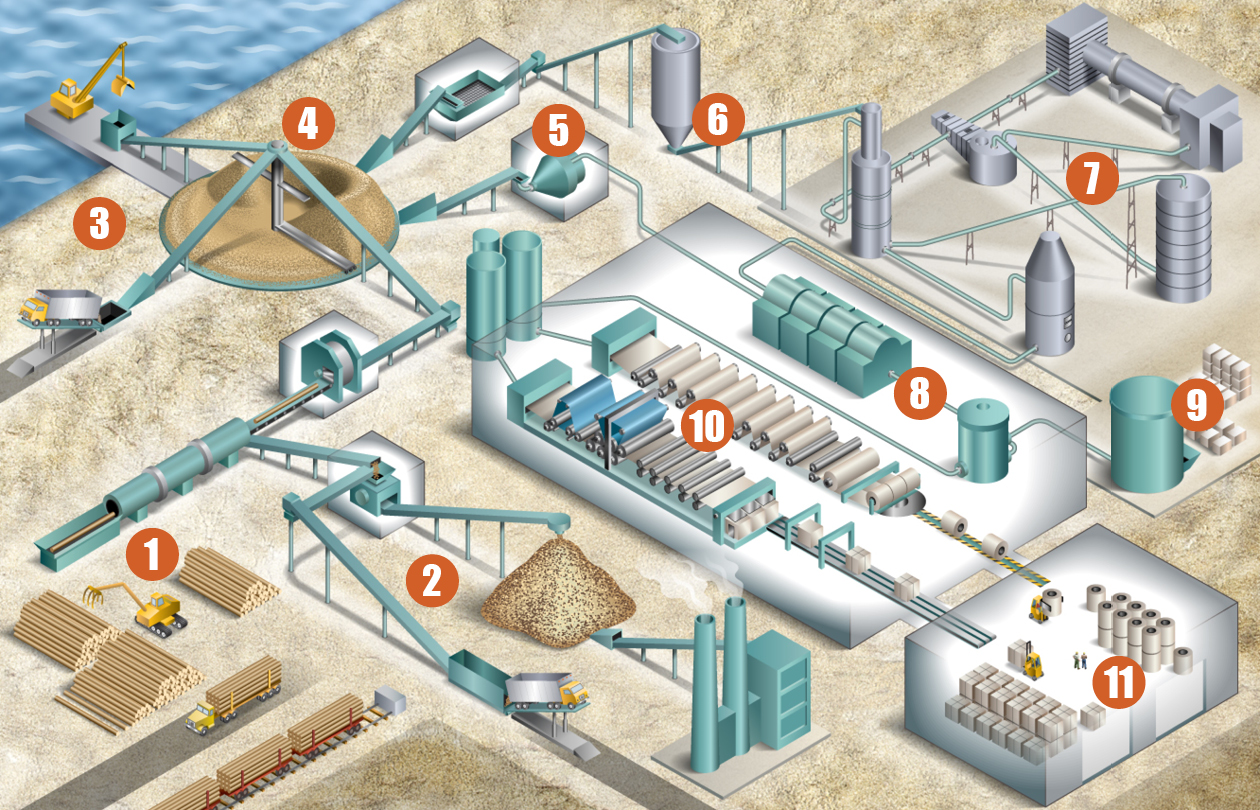

1. Log Processing: Log Truck/Rail Car Unloader — Log Stockpile — Debarker and Chipper — Chip Stockpile

Pulpwood logs are brought in on trucks or rail cars to be debarked and chipped. Once the bark is removed and the logs are chipped, those chips are taken to a stockpile and bark is taken to the bark hog.

ISSUES

- Logs dropping out of the debarker can be 30” in diameter and weigh hundreds of pounds, causing major impact on the belt and splices.

- There will likely be a number of transfers from the chipper to the chip stockpile. The main issue is spillage and material getting agitated and escaping in the load zones.

- High moisture content in chips makes belt slipping likely.

- Belt mistracking, causing spillage in the load zone.

- The materials being handled are flammable, so any kind of carryback is a problem.

- Cleated belts are hard to seal to the chute, causing spillage, and can be hard to clean.

SOLUTIONS

EZP1 Precleaners are a great choice for many hog fuel belts, as these are typically in the 30-42" (900-1050mm) wide range and move 200-300 fpm (1-1.5 M/s).

The MSP Standard Mine-Duty Precleaner or MMP Medium Mine-Duty Precleaner is ideal for chip belts as they are typically in the 30-48" (900-1200mm) wide range, but can be up to 72" (1800mm) wide. Generally, these belts are moving around 400-500 fpm (2-2.5 M/s).

The Y-Type™ Secondary Cleaner with Urethane Blades (on non-cleated belts) tackles wet wood fines that will build up on surfaces quickly on cleaners that aren't designed to shed material. The minimal flat surfaces of this cleaner help prevent material from building up on the blades/cushions, reducing maintenance. Carbide blades are a good option for more stubborn material.

The Motorized Brush Cleaner (on cleated belts). A flat blade precleaner cannot be used on cleated belts. Sometimes segmented secondary cleaners are used, but these are not very efficient. The best option is a brush cleaner that spins opposite the direction of belt travel to dislodge material from the belt and cleats. These cleaners are also effective on flat belts to brush fine material off the belt after a precleaner gets the large material off the belt.

Enclosed Skirt Systems paired with Flex-Lok™ Skirt Clamps or Flex-Seal™ Skirt System and Urethane Skirting help control the dust at the transfers for safety reasons, and these

reduce maintenance costs elsewhere as well. Wood dust getting into idler bearings can cause them to seize up, and failed bearings can be a heat source.

The impact of chips and hog fuel is usually low, but full logs dropping out of the debarker and going to the chipper can be high impact. Slider Beds with Impact Rolls are a great choice for belts carrying chips and hog fuel. These beds provide a solid surface for skirting to seal against, offer support in these low impact areas, and are designed for easy service. For full logs dropping out of the debarker, Flexco DRX™ Impact Beds can be used. Beds as high as the DRX™ 3000 may be required depending on the log size the mill is bringing into the process. These beds will help prolong the life of the belt and are built to withstand high impact, while still offering slide-out service for easy maintenance.

Flex-Lag® Medium Ceramic Lagging (39% lagging) is recommended to minimize slippage as the chip and hog fuel moisture content can be significant. Slipping pulleys can be fire hazards if they heat up enough to ignite, and there is ample fuel for fires with all the chips present.

2. Hog Fuel Processes: Debarker or Truck Dump — Bark Hog — Hog Fuel Stockpile

Hog fuel from the debarker or hog fuel truck dumps goes through the bark hog/hogger to grind it down and then it is conveyed to a stockpile where it is stored until needed in the boiler. The boiler produces steam to generate power for the plant and is used for heating and softening chips during the digestion process.

ISSUES

- The wide range of sizes and shapes makes transferring the material to the bark hog a challenge.

- Stringy bark hangs up on conveyor structure.

- Similar to chips, hog fuel is flammable — it is used for fuel in the boilers so carryback and spillage is a problem.

- When running more material than conveyors were designed for, hog fuel is piled very high on belts and has a tendency to fall off, especially at transfers where material gets agitated.

- Cleated belts are hard to seal to the chute, causing spillage, and can be hard to clean.

SOLUTIONS

EZP1 Precleaners are a great choice for many hog fuel belts, as these are typically in the 30-42" (900-1050mm) wide range and move 200-300 fpm (1-1.5 M/s).

The Y-Type™ Secondary Cleaner with Urethane Blades (on non-cleated belts) tackles wet wood fines that will build up on surfaces quickly on cleaners that aren't designed to shed material. The minimal flat surfaces of this cleaner help prevent material from building up on the blades/cushions, reducing maintenance. Carbide blades are a good option for more stubborn material.

The Motorized Brush Cleaner (on cleated belts). A flat blade precleaner cannot be used on cleated belts. Sometimes segmented secondary cleaners are used, but these are not very efficient. The best option is a brush cleaner that spins opposite the direction of belt travel to dislodge material from the belt and cleats. These cleaners are also effective on flat belts to brush fine material off the belt after a precleaner gets the large material off the belt.

Enclosed Skirt Systems paired with Flex-Lok™ Skirt Clamps or Flex-Seal™ Skirt System and Urethane Skirting help control the dust at the transfers for safety reasons, and these reduce maintenance costs elsewhere as well. Wood dust getting into idler bearings can cause them to seize up, and failed bearings can be a heat source.

Slider Beds with Impact Rolls are a great choice for belts carrying hog fuel. These beds provide a solid surface for skirting to seal against, offer support in these low impact areas, and are

designed for easy service.

Flex-Lag® Medium Ceramic Lagging (39% lagging) is recommended to minimize slippage as the chip and hog fuel moisture content can be significant. Slipping pulleys can be fire hazards if they heat up enough to ignite, and there is ample fuel for fires with all the chips present.

3. Chip Unloading: Chip Truck Dump and Barge Unloader

Chips are taken off trucks or barges and dropped in a hopper. The hopper will likely have a drag chain on the bottom that moves chips to a chute before being dropped onto a belt.

ISSUES

- It is difficult to clean the area where the hoppers drop chips onto the belts.

- Loose chips are difficult to contain on the belt.

- On the long overland conveyor bringing chips from the barge unloading area to the stockpile, mistracking can occur.

SOLUTIONS

Slider Beds with Impact Rolls are a great choice for belts carrying chips. These beds provide a solid surface for skirting to seal against, offer support in these low impact areas, and are designed for easy service.

Flex-Seal™ Skirt System or Flex-Lok™ Skirt Clamps paired with Urethane Skirting will help contain loose material on the belt in the load zone.

EZP1 Precleaners and Y-Type™ Secondary Cleaner with Carbide Blades should be used on belts being fed by the hopper. These are shorter, slower belts. The goal is to keep the barge area clean, but as it is a remote part of the mill, the cleanup requires more time. The shape of the Y-Type™ makes it less susceptible to material buildup, which in this application is important. The chips coming off the barge can have up to 50% moisture content, and the wet fines tend to build up on flat surfaces.

Flex-Lag® Medium Ceramic Lagging (39% lagging) is recommended as the chip and hog fuel moisture

content can be significant. Slipping pulleys can be fire hazards if they heat up enough to ignite, and

there is ample fuel for fires with all the chips present.

The PT Max™ Belt Trainer should be used on the long overland conveyor bringing chips from the barge unloading area to the stockpile if mistracking occurs. These belts will generally be wider as well, so a heavy-duty tracker is the best option. A PT Max™ Return Side Belt Trainer before the tail pulley can help ensure the belt tracks center into the load zone so material holds the belt centered.

MMP Medium-Duty Precleaner and MHS Heavy-Duty Secondary Cleaners may be required on this belt to prevent material from tracking back and building up on idlers and creating fugitive piles.

4. Chip Stockpile

Chips are taken from the chipper, truck dumps, or barge unloader to a stockpile, where they are stored until needed in the pulping process. After stockpile, chips go either to screening (chemical pulping) or refining (mechanical pulping).

5. Mechanical Pulping: Refiner

Chips are taken from the stockpile to the refining machine where rotating discs smash the chips and separate the fibers.

ISSUES

- There may be multiple transfers from the stockpile to the refining machine.

- Belts slipping due to high moisture content in chips

- Belt mistracking, causing spillage in the load zone.

- The materials being handled are flammable, so any kind of carryback is a problem.

- When running more material than conveyors were designed for, chips are piled very high on belts and have a tendency to fall off, especially at transfers where material gets agitated.

- Cleated belts are hard to seal to the chute, causing spillage, and can be hard to clean.

SOLUTIONS

The MSP Standard Mine-Duty Precleaner or MMP Medium Mine-Duty Precleaner is ideal for chip belts as they are typically in the 30-48" (900-1200mm) wide range, but can be up to 72" (1800mm)

wide. Generally, these belts are moving around 400-500 fpm (2-2.5 M/s).

The Y-Type™ Secondary Cleaner with Urethane Blades (on non-cleated belts) tackles wet wood fines that will build up on surfaces quickly on cleaners that aren't designed to shed material. The minimal flat surfaces of this cleaner help prevent material from building up on the blades/cushions, reducing maintenance. Carbide blades are a good option for more stubborn material.

The Motorized Brush Cleaner (on cleated belts). A flat blade precleaner cannot be used on cleated belts. Sometimes segmented secondary cleaners are used, but these are not very efficient. The best option is a brush cleaner that spins opposite the direction of belt travel to dislodge material from the belt and cleats. These cleaners are also effective on flat belts to brush fine material off the belt after a precleaner gets the large material off the belt.

Enclosed Skirt Systems paired with Flex-Lok™ Skirt Clamps or Flex-Seal™ Skirt System and Urethane Skirting help control the dust at the transfers for safety reasons, and these reduce maintenance costs elsewhere as well. Wood dust getting into idler bearings can cause them to seize up, and failed bearings can be a heat source.

Slider Beds with Impact Rolls are a great choice for belts carrying chips and hog fuel. These beds provide a solid surface for skirting to seal against, offer support in these low impact areas,

and are designed for easy service.

Flex-Lag® Medium Ceramic Lagging (39% lagging) is recommended to minimize slippage as the chip and hog fuel moisture content can be significant. Slipping pulleys can be fire hazards if they heat up enough to ignite, and there is ample fuel for fires with all the chips present.

6. Kraft/Chemical Pulping Process

a. Screening

Chips are screened to ensure they are not too small or large to go into the pulping process.

ISSUES

- There may be multiple transfers from the stockpile to screening.

- Belts slipping due to high moisture content in chips.

- Belt mistracking, causing spillage in the load zone.

- The materials being handled are flammable, so any kind of carryback is a problem.

- When running more material than conveyors were designed for, chips are piled very high on belts and have a tendency to fall off, especially at transfers where material gets agitated.

- Cleated belts are hard to seal to the chute, causing spillage, and can be hard to clean.

- Possibility of dust explosions due to dust in the air, carryback, and spillage.

SOLUTIONS

MSP Standard Mine-Duty Precleaner are good for these belts, which generally move around 400-500 fpm (2-2.5 M/s). Visual tension checks and simple blade changes requiring the removal of only one pin make this cleaner an excellent choice for belts conveying chips to screening

The Y-Type™ Secondary Cleaner with Urethane Blades (on non-cleated belts) tackles wet wood fines that will build up on surfaces quickly on cleaners that aren't designed to shed material. The minimal flat surfaces of this cleaner help prevent material from building up on the blades/cushions, reducing maintenance. Carbide blades are a good option for more stubborn material. These cleaners are also designed for fast maintenance. The entire blade cartridge can be changed in a matter of minutes, which is important on these belts preparing the chips to go into the pulping process.

Getting chips from the stockpile at ground level to the top of a building often requires a cleated belt. A flat blade precleaner cannot be used on these belts. The best option is a Motorized Brush Cleaner, which spins opposite the direction of belt travel to dislodge material from the belt and cleats. These cleaners are also effective on flat belts to brush fine material off the belt after a precleaner gets the large material off the belt.

Enclosed Skirt Systems paired with Flex-Lok™ Skirt Clamps or Flex-Seal™ Skirt System and Urethane Skirting help control the dust at the transfers for safety reasons, and these reduce maintenance costs elsewhere as well. Wood dust getting into idler bearings can cause them to seize up, and failed bearings can be a heat source.

Flex-Lag® Medium Ceramic Lagging (39% lagging) is recommended to minimize slippage as the chip and hog fuel moisture content can be significant. Slipping pulleys can be fire hazards if they heat up enough to ignite, and there is ample fuel for fires with all the chips present.

Designed with minimal flat spots for fugitive material to build up, the PTEZ™ Belt Trainer is an excellent choice for pulp and paper mills. Getting chips from the stockpile to the top of a building requires a cleated belt. The PTEZ can be mounted on the smooth side of these belts to keep the belt on track.

Chips that are the correct size fall down through the chip sizers and screens to a belt that feeds the chip silo (sometimes a bucket elevator). Generally, the impact will be low. Slider Beds with Impact Rolls provide a solid surface for skirting to seal against, which reduces time spent cleaning up, and are designed for easy service. Again, dust escaping the load zone is an explosion hazard as these conveyors are often indoors.

b. Chip Silo

After the chips have been screened, they are conveyed to a chip silo. This silo of ready-to-use chips acts as a buffer so chips can still be sent to the digester when maintenance is being done on the screens/slicers or other conveyors upstream.

ISSUES

- Belt mistracking, causing spillage in the load zone.

- The materials being handled are flammable, so any kind of carryback is a problem.

- Cleated belts are hard to seal to the chute, causing spillage, and can be hard to clean.

SOLUTIONS

The MSP Standard Mine-Duty Precleaner and Y-Type™ Secondary Cleaner make maintenance fast and easy. The blades on both of these cleaners can be retensioned or changed in a matter of minutes.

The Motorized Brush Cleaner is recommended on the cleated belts feeding the chip silo to help reduce carryback buildup on top of the silo or on the conveyor structure. This can be a difficult area to access so cleaning material off at the discharge means less housekeeping in a hard-to-reach area.

c. Digester

Chips from the silo are conveyed to the digester where the pulping process begins.

ISSUES

- Unplanned downtime on the weigh feeder under the silo and the conveyor feeding the digester is extremely expensive.

- Very limited maintenance time on these conveyors means fixes have to be made quickly.

- H2S gas is released in the digester as the lignin breaks down. This gas is corrosive to mild steel.

SOLUTIONS

The Stainless Steel MSP Standard Mine-Duty Precleaner with White Urethane Blade and Stainless Steel Y-Type™ with White Blades is recommended in this application because the H2S gas is corrosive. The white urethane blade will also hold up better than standard urethanes in this environment.

The PT Max™ Belt Trainer ensures centered loading of chips and keeps the belt centered the length of the conveyor can help reduce spillage and keep the belt from being damaged by hitting structure. Downtime caused by a damaged belt is extremely expensive at this part of the process.

Slider Beds with Impact Rolls are designed with quick service in mind. The troughs on these slider beds can be lowered for quick change-outs and the rolls can be changed in a matter of minutes.

d. Blow Tank

The cooked chips are sent to the blow tank where pressure changes separate the chips into individual fibers. The individual fibers are what make up the solid portion of pulp.

7. Kraft Chemical Recovery Process

White liquor is used to break down chips in the digester by dissolving the lignin that holds the cellulose fibers together. After cooking, the liquid containing the dissolved lignin is called Black Liquor. This is burned in the recovery boiler, leaving behind only the spent cooking chemicals, and this mixture is called Green Liquor. Lime is added to the green liquor in a causticizer, which converts the green liquor into White Liquor and the cycle starts again. White liquor goes to the digester and the lime mud is sent to the lime kiln where it is dried out to be reused.

a. Lime Kiln

A conveyor belt brings lime mud (calcium carbonate) to a kiln where it is heated and turned into lime (calcium oxide) so that it can be reused. In the recaust process, caustic soda is used in the digester to break down the lignin in the chips, which changes the chemical compounds. Lime is used to convert the spent cooking chemicals back into caustic soda so they can be reused again and again.

ISSUES

- Lime mud carryback builds up on conveyor components and idlers, requiring cleanup and leading to mistracking.

SOLUTIONS

Because these belts are generally slow and narrow, the EZP1 Precleaner is an excellent choice for cleaning this material off the belt. The belt may discharge material very near or even in the kiln, so the Ultra High-Temp (UHT) Blade can be used if the temperature is high.

Due to the high moisture content, the U-Type® Secondary Cleaner is an excellent choice for these belts. The lime belt is often referred to as the "mud belt" due to the consistency of the lime. The U-Type has carbide tips embedded in a rubber blade to shear stubborn carryback and remove water from the belt.

With minimal components for lime to build up on, the PTEZ™ Belt Trainer is a good choice for the lime kiln belt. We recommend mounting this on the "clean" side of the belt if space allows, as that will provide the best traction in this application. It is also recommended that any buildup on idlers be cleaned off as that will allow the trainer to work most efficiently.

The impact in this area is low, but Slider Beds are recommended because sealing is required in the load zone to avoid spilling the slurry-like material that can get into bearings, seizing them and corroding other components around the conveyor.

8. Stock Preparation – Pulping Process

a. Washing

The pulp is washed to remove organic and inorganic compounds. In chemical pulping, this includes the lignin that has been dissolved.

b. Screening

Screens remove clumps of fibers that were not separated in the blow tank or refiner to reprocess them.

c. Bleaching

Not every mill bleaches the pulp, but mills making any sort of white or appearance grade paper will bleach the pulp at this point in the process. Chemicals are used to brighten the pulp and dissolve any remaining lignin.

9. Recycled Paper

Some mills may bring in recycled paper that has been sorted and baled at a recycling facility to add in with the virgin wood pulp they are making. This is delivered to the pulp/paper mill where it is stacked by fork trucks until needed. Fork trucks then place the bales directly in the pulper or on a conveyor that takes them to the pulper. The pulper mixes the paper in lukewarm water and cleaning chemicals and screens out metals, plastics and ink. The remaining pulp slurry is bleached and mixed with the virgin wood pulp and sent to the pulp or paper machine.

The belt carrying the pulp bales to the pulper can be up to 72" wide and moves very slowly. These are commonly 3-ply oil-proof belts. The Rivet Hinged Fastener like the Flexco R5 is a good choice for these belts.

10. Pulp or Paper Making Machines

a. Paper making machine

The papermaking machine, also known as a Fourdrinier Machine turns stock into paper rolls at this point in the process.

b. Pulp Dryer

Water is removed via draining, squeezing, and evaporation producing pulp – a thicker, heavier product than finished paper. The pulp is sold to non-integrated paper mills which repulp it and run it through a papermaking machine.

In the paper machine area, there may be a few broke belts. Broke is a term for unusable paper that comes from sheets that have been trimmed during normal operations, paper that was not finished for some reason, or paper that has broken inside the paper machine and was pulled out. Broke paper cannot be spooled and sold, so it is re-pulped and sent back through the paper machine.

Broke belts may be around 54-60" (1350-1500mm) wide and carry broke to the re-pulper. Flexco Rivet Hinged Fasteners like the R5 are a good choice for broke belts. The hinged fastener can wrap around the broke belt pulleys, which can be quite small.

11. Storage/Shipping

Paper rolls or pulp bales are taken to storage, shipped to customers, or if the mill has a converting operation, they may go on to be made into many different types of paper products in a separate converting area.

Paper rolls are commonly conveyed via in-floor, V-type slat conveyors which use a series of linked metal plates to move rolls. The rolls can be placed on the ground and rolled onto these conveyors which take them to storage/shipping.

Some paper mills use belt conveyors to move rolls that have been slit to smaller sizes to warehousing/storage/shipping. Light conveyor belts handling rolls are typically PVC, up to 3-ply, and rated for use in heavier product conveying. These lightweight belts may be vulcanized to avoid leaving impressions in the paper surface, but some mills may use mechanical fasteners.

- The Novitool® Aero® Splice Press is a good choice for splicing these PVC belts.

- Clipper® Wire Hooks can be used if the mill wants to use mechanical fasteners.