Flex-Lag® Weld-On™ Ceramic Pulley Lagging Eliminates Slippage, Extends Belt Life

Industry

Paper

Application

Recycling Belt

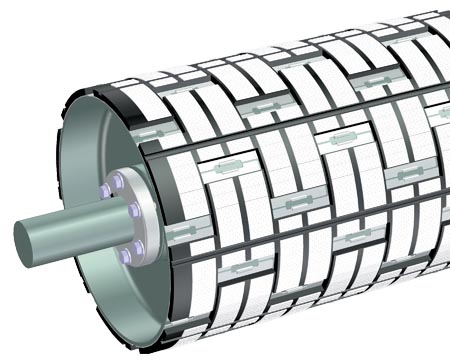

Product

Flex-Lag® Weld-On™ Ceramic Pulley Lagging

Objective

Prevent belt slippage and mistracking

Extend belt life

Conveyor Detail

48” 3-ply 330 belt with a 24” diameter pulley

Problem:

An East Coast paper plant found an issue with the belts that recycle the product that falls off the main belts at its facility. The four belts that are used for this task operate on a slight incline and see a lot of water during the process. The serpentine drive that was used on these belts was experiencing a lot of slippage on the drive pulley. The diamond rubber lagging they were using did not work well because the water would not allow the rubber to grip the belt. The belt was also mistracking because of the slippage of the belt on the pulley.

Solution:

Frustrated with slippage and mistracking, the operations manager brought someone in to take a look at the problem. The local distributor suggested Flex-Lag® Weld-On™ Ceramic Pulley Lagging from Flexco because of its exceptional performance in wet conditions. The operations manager decided to give it a shot and was intrigued with the fact that the lagging could be cut and put into place without removing the pulley.

Result:

Once the lagging was installed, both the slippage and mistracking issues were resolved, extending the life of the belt and ensuring the product stays on the belt. The ceramic lagging is also lasting much longer than the rubber lagging in this application. The operations manager has plans to put the lagging on the rest of the drive pulleys in the near future because of its performance and because of the quick installation time associated with the convenient strips.

Product Group

- Bondable and Weld-On Pulley Lagging

Product Line

- Flex-Lag® Weld-On™ Pulley Lagging

Industry

- Wood Products