Discover Industrial Baking Belt Conveyor Solutions

With strict sanitary concerns, costly downtime incidents, and ever-increasing product demand, the team at Flexco knows that running your belt conveyor system at peak performance is crucial.

Flexco Understands Industrial Baking

As an industrial baking facility, you have many causes for concern in your food processing production. From operating within highly stringent sanitation standards to meeting the demand of your customers, there is a real need for keeping an efficient belt conveying process in place.

To run your system at the highest possible level, utilize the expertise of Flexco.

As a longtime partner of the food processing industry, Flexco has made it a goal to develop solutions that address your most painful problem areas. With industry-leading conveyor belt repair and installation tools and fast-acting belt cleaning systems, our team has engineered a catalog of products that keep your belt conveyor running smoothly.

Although our products are generally what gets our customers' attention, it is not what keeps them wanting to work with us. Instead, it is in our “Partners in Productivity” approach. When you work with Flexco, you don’t just get a product for your belt conveyor system, you gain access to a dedicated team of service professionals, distributors, and territory managers that share one common goal: your success.

Interested in learning more about how Flexo works hand-in-hand with the industrial baking industry? Discover our latest products, training resources, interesting application stories, and so much more below.

A Clean Facility is a Profitable One

Keeping your belt conveyor system clean is paramount for food processing facilities.

Not only does utilizing a tool like a food grade cleaner lead to safer conditions for consumers, but it also saves plants time and money.

See how much you could be saving in your first year by using Flexco’s FGP Food Grade Primary Cleaners with our first-year return calculator.

THE INDUSTRIAL BAKING PROCESS

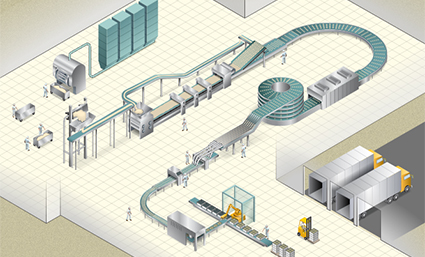

FOR BREAD

The volume of bread that needs to be produced to meet consumer demand is astounding. Even more impressive is the process that goes into producing an adequate amount.

Having extensively worked with partners in the food processing industry, we are acutely aware of the day-to-day problems that arise with bread production.

Our Bread Process Map is an excellent resource for learning about the key problem areas of belt conveyor systems, and how you can better address them head-on. Check it out below!

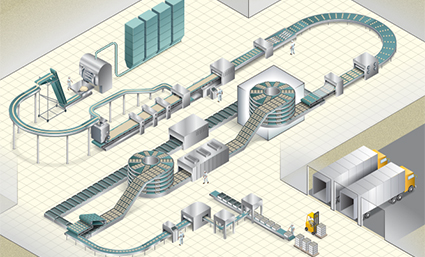

THE INDUSTRIAL BAKING PROCESS

FOR COOKIES AND CRACKERS

As a specialty baking operation, cookie and cracker manufacturers face challenges that are vastly different from their general industrial baking counterparts.

With unique heating and cooling measures, sandwiching stations, and varied frosting and topping needs, there are plenty of areas that need attention in the belt conveying process.

Discover how each section of your system can be addressed in our Cookies and Crackers Process Map.

FEATURED PRODUCT FOR INDUSTRIAL BAKING

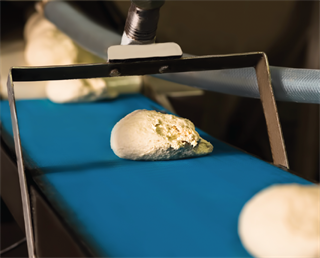

Ensuring efficient belt conveyor output for industrial baking facilities begins with the belt itself.

For a seamless splice that runs smoothly, turn to the Novitool® Aero® Splice Press . Our self-contained endless splicing system allows users to create effective and superior splices, all in under 10 minutes.

See how you can bolster your performance and save your facility downtime and operating costs with our Flexco Baking Calculator.

Solutions for Food Processing

Make sure you use the best belt conveyor products by checking out our top solutions. Flexco offers the very best in on-site and preventive maintenance. Discover why we are the industry standard for mechanical belt fasteners, belt cleaning systems, and so much more.

Belt Cleaning Systems

The cleaner the conveyor belt, the better the long-term performance. Our conveyor belt cleaning systems reduce carryback material, prolonging belt lifespan. Whether you need a primary cleaner, secondary cleaner, or a cleaning accessory, Flexco has you covered.

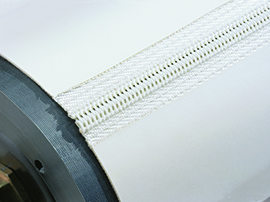

ENDLESS SPLICING SYSTEMS

Designed for light-duty industries, our endless conveyor belt splicing tools create a seamless splice for the long-term. From plied thermoplastic to homogeneous belting, we have the right solution for your facility.

Mechanical Belt Fasteners

Flexco has led the way in belt fastening systems for over 100 years. Our end goal in designing belt fasteners is to maximize our customers' output. By factoring in belt thickness, PIW, and pulley diameter, we can develop the best customized solution for your operation.

CONVEYOR BELT MAINTENANCE TOOLS

Having the right tools on hand can make repairs, maintenance, and installation a breeze for your belt conveyor system. Discover how you can make a more efficient process, all while keeping your workers safe with our belt maintenance tools.

Education and Training

Flexco University is an incredibly convenient outlet for training on material conveying. With in-class, on-site, and virtual education options, there is a training option available for everyone.

GET INDUSTRIAL BAKING INDUSTRY UPDATES!

Stay in the loop on the latest industrial baking news with Flexco!

Our subscribers will be the first to hear about key policy changes, new product offerings, thoughtful blog posts, and so much more.

Sign Up