Flexco Dual Seal Polyurethane Skirting Reduces Clean-Up, Protects Belt

Industry

Tunneling

Application

Infrastructure Construction

Product

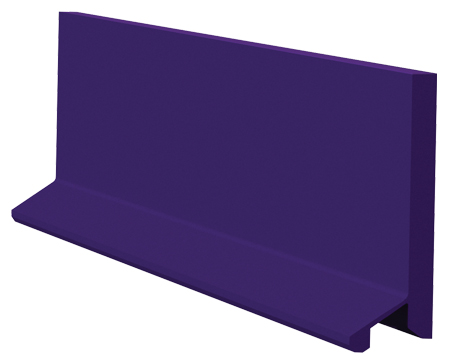

Flexco Dual Seal Polyurethane Skirting

Objective

Decrease spillage

Conveyor Details

1400 mm wide, 15 mm thick, 50 meter long high angle conveyor belt

Problem:

The site supervisor of an extensive infrastructure project in Europe was having a major issue with spillage on their high-angle conveyor belt. Because of the speed of the belt, their existing dual seal polyurethane skirting was deteriorating rapidly and needed to be replaced every two to three months.

Solution:

During a routine visit, Flexco’s regional sales representative and the local distributor were alerted to the supervisor’s paint point. After inspecting the area, they recommended the installation of Flexco Dual-Seal Polyurethane Skirting in the critical conveyor area. The easy-to-adjust design makes on-site modifications safer and simple for workers. A secondary seal provides a floating contact area behind the main slab to prevent spillage.

Result:

Upon installation, the success of the Flexco Dual Seal Polyurethane Skirting was immediate. The two contact points that run the entire length of the skirtboard not only prevented material spillage, but also significantly decreased dust emissions, leading to a cleaner overall plant. The Dual Seal Polyurethane has also already lasted three times longer than the previous skirting. The manpower that previously cleaned the spillage has been reassigned to other areas. Keeping the belt up and running is vital to the success of the project, so the unexpected bonus of a softer skirting was well received by the supervisor. Flexco Dual Seal Polyurethane Skirting not only discourages damage to the conveyor belt, but also maintains a high tear resistance to ensure a long, functional life in a tough tunnelling application.

Product Group

- Impact Beds and Skirting Systems

Product Line

- Skirting Systems

Industry

- Underground Mining