Flexco Food Grade Primary Cleaners Cut Costs and Repairs for Major Food Processing Facility

Product Group: Belt Cleaning Systems

Product Line: FGP Food Grade Primary Cleaner

Industry: Industrial Baking

Application: Tortilla Dough Sandwich Incline Conveyor

Product: FGP Food Grade Primary Cleaner

Objective: Reduce product waste, Reduce downtime, Reduce maintenance time, Reduce blade replacement frequency

Conveyor Detail: 2-Ply White PU Synthetic

Problem:

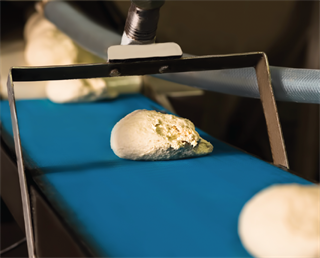

A dough processing plant located in the eastern United States was facing issues with carryback and dough loss on one of their lines. The homemade cleaning systems they had in place on their incline sandwich conveyors were two silicone blade assemblies. A dough sheet traveled upwards between the 2-ply white PU conveyor belts across the two blades at the discharge and down into a hopper for further processing. While silicone has great dough-release properties, the blades began to wear badly in a very short period of time. Additionally, the site's larger sheets of dough caused intense pressure on the blades which caused them to fluctuate, allowing dough to collect in unintended areas around the conveyor. The customer was also concerned about sanitation levels as well as potential contamination of the finished product, so they sought out a more long-term, better solution.

Solution:

To better address the health of their belt, the plant manager decided to contact his Flexco representative for a site walkthrough. While at the facility, Flexco’s Food Processing Industry Manager noted that a potential solution could be found by upgrading their belt cleaning systems to Flexco FGP Food Grade Primary Cleaners (FGPs). The FGP works well with specialized food-specific belt materials, features a small enough footprint to fit many systems, and has consistently demonstrated effectiveness for similar applications. An additional concern voiced by the plant manager was the location of the belt in question. At 15 feet above ground-level, they wanted a solution that would lower the frequency their maintenance team would have to address issues, as access to the belt cleaning system was often restricted. Taking that into account, Flexco’s representatives clearly communicated that maintenance to the FGP is minimal, and the strength and wear-resistance of the blades considerably reduce the likelihood of repairs and replacement.

Result:

After installing an FGP Food Grade Primary Cleaner on both incline conveyors, they noticed an immediate impact. Not only did they see a significant improvement in the damage the previous blade was incurring due to wear and tear, but there was also a drastic reduction in dough carryback. Additionally, they noted that the need for maintenance team visits has decreased substantially, freeing them up for more pertinent issues across the plant. The plant manager was so satisfied with the performance of their FGPs that they have begun expanding the use of other Flexco cleaners in areas along their belt conveying processes in order to improve production efficiency and cleanliness.

Product Group

- Belt Cleaning Systems

Product Line

- FGP Food Grade Precleaner

Industry

- Industrial Baking