Protein Industry Spotlight: Reduce Sanitation Time With One Change to Your Belt Conveyor

|

| Beef scraps fall to the floor, prompting more clean up and sanitation time. |

When it comes to pinpointing the most pressing issue within a processing plant, you’ll get dozens of different answers from dozens of different people. From maintenance, you’ll get downtime and manpower. From food safety and quality, you’ll get cleaning and sanitation. From operations, you’ll get “all of the above.” So where do sanitation, downtime, and manpower all meet to become one pressing issue? On your conveyors.

It all starts with sanitation

Sanitation 101 is one of the first things you learn when you start working at a proteins plant. Regulatory agencies make sure everyone is talking the talk and walking the walk when it comes to keeping food safe from allergens, bacteria, and chemical hazards. Depending on your facility and the variety of proteins you process, you may shut down once, twice, or even three times a day to wash, rinse, and sanitize your conveyor belts.

This process can take hours each time, which monopolizes the maintenance team – with sometimes the whole team pitching in to get the job done more quickly. That means other tasks that could be accomplished during that time have to wait. And who has more time these days? Here is where your pressing issue starts affecting your bottom line and gets the attention of upper management.

The question is: how do we conserve resources – time, manpower, and even water – when it comes to the sanitation of our conveyor belts?

Combine a recent labor shortage with the spotlight on how we are sanitizing everything as much as possible, and you have a very hot topic. Food Safety Magazine even talked about the importance of conserving resources when it comes to sanitation in this article. New technologies have come forth to limit water and chemical usage, including more precise water and chemical targeting and electrostatic methods, and an increase in automation can help reduce the amount of manpower used during the cleaning process.

But what if you could minimize the amount of residual protein scraps and fat on the belt when the time comes to sanitize with just one small change to your conveyor?

Enter the engineered belt cleaner

|

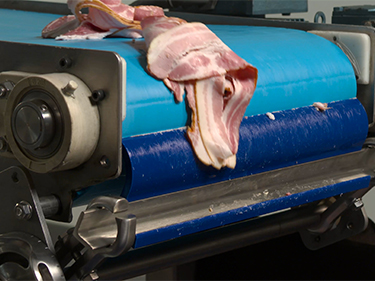

| Bacon is effectively scraped off the belt before it can fall to the ground and stick to the conveyor thanks to an engineered belt cleaner. |

Equipping your conveyor with a cleaner that is specifically engineered to work with the types of belting used in the food processing industry can make an immediate impact on the time spent sanitizing your conveyor belt. Engineered belt cleaners contain tensioning mechanisms for optimal interaction between the cleaning blade and the belt, scraping off meat, pork, chicken, and other proteins before they make their way around the pulley to stick to your conveyor frame and components or fall to the floor.

And as an added bonus, this simple act of scraping food off the belt not only reduces sanitation time, but also keeps the food in the processing stream so you aren’t sweeping your profits up off the floor once production is done.

But what if I already have a cleaner on my belt? One that is bolted on to the conveyor, a simple piece of rubber or plastic? Without the ability to automatically tension – keeping the blade in constant contact with the belt – you not only have an ineffective cleaner, but you could have one that develops a gap between the belt and the blade, allowing even more food to collect and requiring additional time to unbolt the cleaner blade in order to properly sanitize.

Instead, you will want to focus on engineered cleaners that are designed specifically for the food industry and made from food grade materials. Choose cleaners that are designed to ensure that cleaning and sanitizing the conveyor, as well as the cleaner itself, is quick and easy. For extra peace of mind, food operations should seek out engineered cleaners that meet strict sanitary guidelines, like those that contain no mechanical hardware located directly in the flow of the processed food product.

The FGS Food Grade Secondary Cleaner From Flexco

The FGS Food Grade Secondary Cleaner is easy-to-install and features solid, stainless steel components to make it easy to maintain. Cleaning and sanitation is a snap, featuring quick and easy disassembly in less than a minute, with limited components and no need to remove the cleaner from the structure. And this cleaner has the flexibility to have the blade contact at the discharge/head pulley of the conveyor or in a trailing position with the blade, making contact on the return side of the belt, after the head pulley.

But don’t take our word for it. See it in action here:

Still not sure about how an engineered belt cleaner would work in your facility?  and then

and then  to identify the conveyors in your facility that would benefit most from an engineered cleaner.

to identify the conveyors in your facility that would benefit most from an engineered cleaner.

Authored by: Jonathan Morgan, Industry Manager – Food Processing

As an Industry Manager at Flexco, Morgan focuses on the food processing industries, including proteins, baking, and produce. Morgan has a mechanical engineering education, application knowledge, extensive industry network, and technical sales support experience.

Subscribe to the Flexco Blog

Related Blogs

Published Date

January 12, 2022Product Group

- Belt Cleaning Systems

Industry

- Proteins

Issues

- Carryback

- Downtime

- Maintenance

- Product Loss

- Sanitation